News & Events

Characteristics and methods of castings

Casting is a forming method in which molten metal liquid is poured into a mold similar to the shape of the part, and after cooling and solidification, a blank or part with a certain shape and performance is obtained.Read more >>Why are T-slots on T-slots platform easy to error?

The T-slot platform is often very prone to errors in the T-slot planed by the platform due to operating errors. The following four are the main reasons.Read more >>Inspection content of casting blank

1. Casting defects Common casting defects of casting blanks include: porosity, shrinkage cavity, shrinkage porosity, slag inclusion, sand hole, crack, cold partition, drape, burr, sand sticking, bulging sand, insufficient pouring, damage, size deviation...Read more >>Types and functions of cast iron cube tables

The cast iron cube table is mainly used for the inspection of the parallelism and perpendicularity of the parts and supports the workpiece during scribing. One of the working surfaces has a V-shaped groove;Read more >>Introduction of the main process of cast iron platform

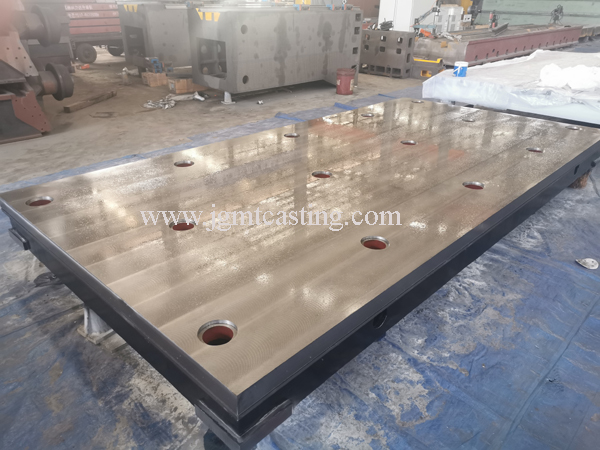

Design of the cast iron platform: According to the design drawings of GB/T7974-1999 by our professional designers in accordance with your bidding documents, it will be used as the official processing drawing of the contract equipment after verification by both parties.Read more >>The casting methods of cast iron tables

Small cast iron tables generally use resin sand. On the one hand, it is to facilitate sand removal. There are also the following reasons:Read more >>